Vougamoldes has facilities with a covered area of 810 square meters for production and 270 square meters of office and administration area, which enables it to execute molds with great precision and weighing up to five tons.

We materialize the idea of the client

Dedicating around 80% of its total production to the automotive market, Vougamoldes sees Spain as its most representative export market. Parallel to the project of internationalization to which the company has dedicated, the exploration of new markets such as Angola or Mozambique may be part of the future of Vougamoldes, although these countries are not yet technologically prepared to have the desired return. This sector is currently in a contraction with the crisis installed in the national territory, because, increasingly, new solutions are sought, both for the domestic market and for the external market.

In the developing of the Projects of Vougamoldes, the company has been betting on Solidworks since 4 years as a tool of excellence for the development of the most varied projects, from the simplest to the most complex. We have 2 licenses of SOLIDWORKS Professional from the latest version of the market.

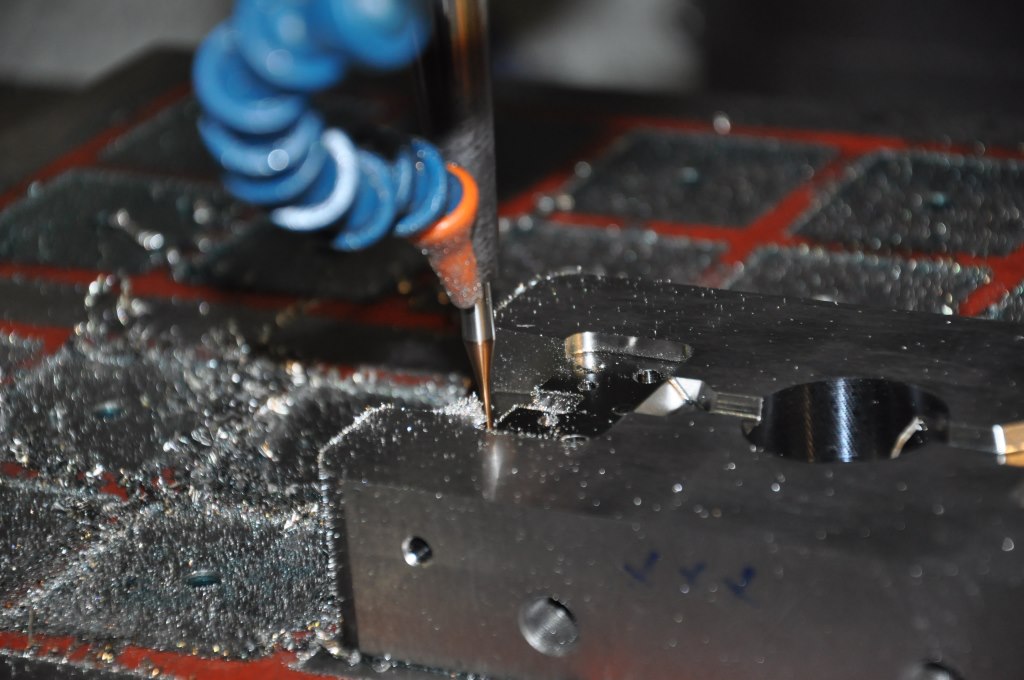

In programming of machine code Vougamoldes uses the preferentially Depocam software for its graphic simplicity and usability and processing power with precision in the most varied scenarios. We have 2 licenses of Depocam from the latest version of the market. Vougamoldes also has 2 Mastercam licenses of the most current version for assistance in both CAD and CAM tasks.

In EDM code programming we have own software developed in-house.

Vougamoldes has 7 computerized numerical centers (CNC) with Fagor command, with 3 axes, and with a maximum working capacity of 1300x800x700. We also have 3 electro-erosion machines one of them with computer numerical control and with maximum working area of 500x400x500.

We also have other machines for the manufacture of molds such as grinding and boring machines for slabs and with drilling capacity with cannon drills.

We have 4 work stations / workbenches for adjustment / mold assembly